http://e-info.org.tw/node/118015

不傷環境一樣柔軟 「菇菇皮革」以低成本搶攻市場

文字大小

3000 1 Share2

本報2016年8月30日綜合外電報導,范震華編譯;賴慧玲審校

視覺效果和觸感跟真的皮革一樣,就連尺寸也能跟一張全牛皮一樣大小——美國舊金山新創公司MycoWorks研發出一款革命性的材料,這種「皮革」不是來自集約化的養殖工廠,而是以蘑菇等真菌為原料製成,不僅柔軟、可塑性高,又防風、防雨,預估再過一兩年即可進入產業鏈,成為你我腳上鞋子的原料。

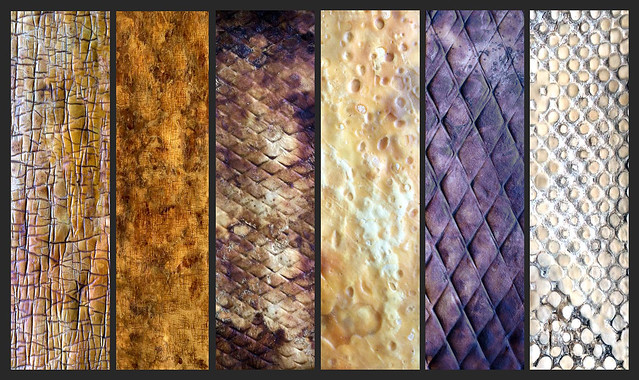

MycoWorks 正在研發各種質感的真菌皮革。圖片來源:MycoWorks提供。授權方式:media use。

「真菌是工業原料的未來式。」MycoWorks認為,這種新材質可望用於建築、電池、汽車、服飾、甚至航太等產業上。今年七月,MycoWorks 已與兩家製鞋公司成為合作夥伴,要將這種新材質打入市場,取代動物皮革和發泡材質。

穿上真菌皮革不傷心 環保、動保人士都愛

真菌皮革的發明,有機會終結各種動物皮革。以往,一張牛皮要花上三年時間飼養牛隻,但是同樣大小的真菌皮革只需幾個星期就能收成;過程中也不會有任何動物受苦,更省下飼養動物消耗的大量資源。

此外,菇類的栽植可以在封閉循環中進行,真菌皮革幾乎不會有碳排放。

「一般來說,栽培菇類用的基質最後都可以直接丟棄,任其腐爛。」MycoWorks 共同創辦人及技術長洛斯(Philip Ross)表示。同時,每批植物性廢料都能長出很多真菌以加工製成皮革,剩下不用的廢料還可轉賣給農場做肥料。

真菌皮革還有另一層好處,常用於培養菇類的基質──如玉米芯等植生原料──在它們身為植物時,生長期間會吸收二氧化碳;死亡、經分解後,二氧化碳就會重新回到大氣;但若被轉換成真菌皮革這類的新材質,就能將二氧化碳捕捉並「固定」在鞋子上。

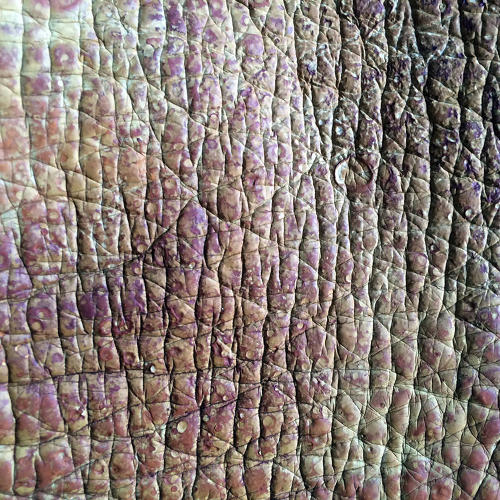

MycoWorks研發的真菌皮革看起來就像牛皮一樣。圖片來源:MycoWorks提供。授權方式:media use。

皮革質感任你選 化學除臭劑也不用買了

MycoWorks表示,只要改變真菌皮革的製成條件,就能有不同成果——鱷魚皮質感、甚至完全不同於動物皮革的新奇材料都有可能。

「我們可以在蕈類的生產過程中,精準地操控其組織密度,這種效果是生產動物皮革時無法掌握的。」洛斯進一步補充。設計師也能藉由掌握真菌皮革的密度,符合不同的吸水性需求。

不僅如此,真菌皮革還可作為「益生菌」的溫床,提供益菌生長的環境,消費者也不需要對著鞋子噴灑化學除臭劑了。

決勝點在於... 成本低廉不輸傳統皮革

儘管吸引了動保與環保界人士的高度興趣,但洛斯認為,真菌皮革最大的成功潛力,還是在於能與傳統皮革一較高下的低廉成本。

2013年MycoWorks剛成立時,洛斯和執行長蘇菲亞(Sophia Wang)致力於發展以菌絲體為主要成分的磚塊,希望能以此取代傳統建材。但建商算盤一撥,發現這種「真菌磚」每平方英呎需花費50美元(約新台幣1591元),比木材、軟木、合成塑料都要來得高,讓MycoWorks苦無市場發揮,直到服裝產業去(2015)年對真菌材質產生興趣,MycoWorks便把握機會推出真菌皮革,趁勢而起。

洛斯指出,「人們總是樂於推銷他們身上穿戴的特殊材質,並引以為傲,但卻不太會談論住家用的建材。人們不會像炫耀手錶一樣談論建築用的石膏板。」

MycoWorks 計畫明年在舊金山灣區開設生產基地,初期產品的成本與高檔皮革相當,但預估在未來四年內,真菌皮革的產量提高,每平方英呎的成本即可調降至五美元(約新台幣159元),足以打入競爭激烈的皮革市場,與傳統皮革一較高下。

真菌皮革「不僅僅是道德和意識型態的議題,其低廉的生產成本還可大大提高市場的接受度。」洛斯表示。

運用真菌皮革製作的長夾樣品。圖片來源:MycoWorks提供。授權方式:media use。

目前,MycoWorks 已經提供樣本給鞋子設計師,期待新的創作材質能激發他們的靈感,希望在今年底完成第一代真菌皮革鞋的設計原型。

未來,真菌皮革有機會以低調的姿態慢慢融入消費者的生活。「我們不會刻意標榜為『環境友善』(good for the environment)產品,」蘇菲亞表示,「因為該產品就是『環境的化身』(It is of the environment)。」

順利的話,真菌皮革鞋將在 2017年上半年問世。

※ 本文轉載自環境通訊網

【相關文章】

【參考資料】

- Tech Insider(2016年7月14日),Everything you own could one day be made from mushrooms

- Co.Exist(2016年7月29日),This Beautiful Carbon-Neutral "Leather" Is Grown From Mushrooms

- KQED Science(2014年8月26日), A House Made From Mushrooms? An Artist Dreams of a Fungal Future

Everything you own could one day be made from mushrooms

Most people look at mushrooms as an ingredient in risotto or a one-way ticket to a psychedelic wonderland. Sophia Wang sees a different future for fungi.

Sitting on the back porch of a San Francisco coffee shop, she fans a piece of worn, indigo-colored leather made from fungi grown in her company's lab.

"It's a new thing in the world," Wang, CEO and cofounder of MycoWorks, says of the mushroom-like material.

Sophia Wang, CEO and cofounder of MycoWorks. JJ Casas/845a.com

The San Francisco-based startup is engineering a sustainable and versatile material from fungi that may one day be used to build houses, batteries, cars, apparel, and even spaceships. According to MycoWorks, fungi is the industrial material of the future.

This week, the company announced it's partnering with two global footwear companies to bring fungi apparel to the market. MycoWorks' soft, malleable, and weatherproof materials will replace leather and foams in shoes.

When the footware companies approached Wang and her cofounder Phil Ross, a sort of fungi evangelist, about replacing the traditional leather in its goods, the appeal was obvious. In the apparel industry, MycoWorks could sell handcrafted, organically made shoes and accessories at a high margin because people expect to pay a lot for premium goods.

They're not made from mushrooms, exactly, but rather, their roots.

Mycelia. Wikimedia Commons

Mycelia are thread-like masses of fungi that grow underground. They run through almost every square inch of earth, delivering nutrients and allowing plants to "talk" to each other.

In an underground workshop in the city, Wang, Ross, and a lean team of artists, biologists, and mycologists (or fungi specialists) are giving new life to millennia-old mycelia.

They take fungi from nature and place small pieces of the mycelia tissue into jars of discarded organic material — corn husks, sawdust, and other agricultural waste that would otherwise rot or be burned. In three to seven days, the mycelia fibers expand, web, and form clumps of material.

Phil Ross, CTO and cofounder of MycoWorks. JJ Casas/845a.com

The team removes this new growth and places it into molds of every shape and size. The material hardens and dries before being fired up in an oven.

Ross compares production to making ravioli from scratch.

"It's handcrafted, locally grown, artisanal fungus," he says, half-jokingly.

"Small-scale, small batches," Wang says.

With a little engineering, the final product can be nearly anything: sturdy or flexible, heavy or lightweight. It may be shaped like a cement brick or laid thin like the lambskin leather in a woman's clutch. It's more resilient than concrete and easily composted.

MycoWorks

When the company was founded in 2013, Wang and Ross worked on developing mycelia-based bricks that could replace common construction materials. But the housing developers they pitched expected the commodity to match prices of materials that have been used in the industrial sector for centuries. Every square foot of mycelia material costs $50 to make — a cut above the cost of wood, cork, and synthetic plastics.

MycoWorks struggled to find a market. So when the apparel industry came knocking in 2015, the company jumped at the opportunity.

A residency at the biotech startup accelerator IndieBio this year helped MycoWorks craft its vision for the future.

"People always advertise the materials that are on their bodies and very proudly tell their stories, and that doesn't seem to be the case with home-building," Ross says. "People don't talk about their drywall in the same way they talk about their watch."

MycoWorks

MycoWorks has already provided samples to artisans for inspiration and expects to prototype their designs before the end of the year. We may see mycelia-infused products on sale as early as 2017.

The company is running a battery of tests to gather more information about fungi products. Buyers will want to know how the mycelia leather holds up to high temperatures and normal wear and tear. Will it decompose over time? (They're unsure.) Does it smell? (Not really, I determined after taking a whiff.)

Wang and Ross plan to move beyond apparel once funds are available for further testing and large-scale manufacturing. They're looking to automation, which could help reduce the cost of producing mycelia to $5 per square foot by 2020.

If MycoWorks gets its way, materials made from fungi might someday blend into our environment without fanfare. They won't be marketed as "good for the environment."

"It is of the environment," Wang says.

沒有留言:

張貼留言